Programmable Logic Controller (PLC): Working Principle:

A Programmable Logic Controller (PLC) is an industrial digital computer designed to perform control functions, primarily for manufacturing processes such as assembly lines, robotic devices, or any activity requiring high reliability, ease of programming, and process fault diagnosis. Understanding the working principle of a PLC is crucial for grasping its significance in industrial automation.

Components of a PLC

1. Central Processing Unit (CPU):

The brain of the PLC, it processes instructions from the control program and manages the data flow.

2.Memory:

Stores the control program and the data necessary for the PLC to operate. Memory types include RAM for temporary data storage and ROM or EEPROM for permanent storage of the control program.

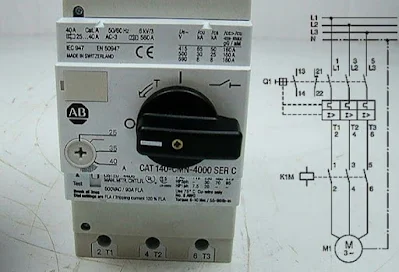

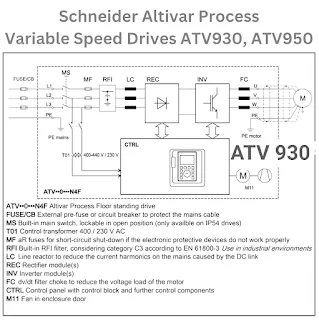

3. Input/Output (I/O) Modules:

Interfaces for connecting external devices to the PLC. Input modules receive signals from sensors and switches, while output modules send control signals to actuators like motors and valves.

4. Power Supply:

Provides the necessary electrical power to the PLC and its components.

5. Communication Interfaces:

Allow the PLC to communicate with other PLCs, computers, and Human-Machine Interfaces (HMIs) for monitoring and control.

Working Principle

1. Input Scan

The PLC operation begins with the input scan. During this phase, the PLC checks the status of all input devices connected to it, such as sensors, switches, and other data sources. The input modules convert the analog or digital signals from these devices into a format that the CPU can process.

2. Program Execution

After scanning the inputs, the PLC executes the control program stored in its memory. This program is typically written in a specialized programming language such as Ladder Logic, Function Block Diagram (FBD), or Structured Text (ST). The CPU reads each instruction in the program sequentially, performs the necessary logic operations, and determines the corresponding outputs based on the input conditions.

For example, a simple control program might involve an if-then logic: if a sensor detects an object, then activate a conveyor belt. The CPU processes this logic and updates the status of the outputs accordingly.

3.Output Scan

Once the program execution is complete, the PLC moves to the output scan phase. In this phase, the CPU sends the updated status to the output modules, which then control the connected actuators. The actuators perform the desired actions, such as turning on a motor, opening a valve, or starting a machine.

4.Housekeeping

The final phase involves housekeeping tasks, such as internal diagnostics, communication with other devices, and updating internal registers. The PLC ensures that all systems are functioning correctly and prepares for the next input scan.

Scan Cycle

The entire process from input scan to housekeeping is known as the scan cycle. A PLC continuously repeats this cycle, usually within milliseconds, ensuring real-time control of industrial processes. The speed and efficiency of the scan cycle are critical, as they determine the PLC’s ability to respond to changes in the input conditions promptly.

Advantages of PLCs

1. Flexibility:

PLCs can be reprogrammed to adapt to new processes or changes in production lines without requiring extensive rewiring or hardware modifications.

2. Reliability:

Designed for harsh industrial environments, PLCs are robust and can operate continuously with minimal downtime.

3. Ease of Programming:

User-friendly programming languages and interfaces allow engineers to develop and modify control programs quickly.

4. calability:

PLC systems can be expanded by adding more I/O modules, making them suitable for both small-scale and large-scale applications.

5.Integration:

PLCs can easily integrate with other industrial systems and devices, enabling seamless automation and data exchange.

Applications

PLCs are widely used in various industries, including automotive, food and beverage, pharmaceuticals, and manufacturing. They control processes such as assembly lines, packaging, material handling, and robotic operations. By automating these processes, PLCs improve efficiency, reduce human error, and increase productivity.

Conclusion

The working principle of a PLC revolves around a continuous scan cycle that involves input scanning, program execution, output scanning, and housekeeping tasks. This cycle ensures real-time monitoring and control of industrial processes, making PLCs indispensable in modern automation. Their flexibility, reliability, ease of programming, and integration capabilities make them a preferred choice for industries aiming to enhance operational efficiency and productivity.

.webp)

.webp)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.gif)

.jpeg)

.webp)

.webp)

.webp)

.webp)