Understanding the Working Principle of Variable Speed Drives (VSD) with a Focus on ATV (Altivar) Drives

Variable Speed Drives (VSDs), also known as Adjustable Speed Drives (ASDs) or Variable Frequency Drives (VFDs), are crucial in modern industrial applications for controlling motor speed and improving process control. This article delves into the working princ

iple of VSDs with a particular focus on ATV (Altivar) drives, which are widely recognized for their efficiency and reliability.

Introduction to Variable Speed Drives

VSDs are electronic devices that control the speed and torque of electric motors by varying the motor input frequency and voltage. This ability to adjust the motor speed is essential in applications where the process requires different speeds at different times, leading to enhanced performance, energy savings, and extended equipment life.

Working Principle of VSDs

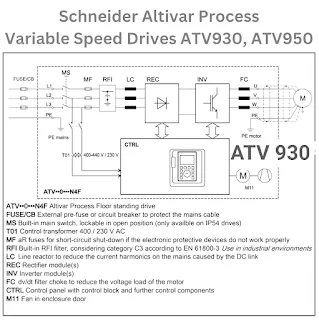

The primary components of a VSD include a rectifier, a DC bus, an inverter, and a control unit. Here’s a breakdown of their functions:

1.Rectifier:

The rectifier converts the incoming AC (Alternating Current) power supply to DC (Direct Current). This stage often uses a diode bridge rectifier.

2. DC Bus:

The DC bus consists of capacitors that smooth out the DC signal, ensuring a stable and consistent DC voltage is supplied to the inverter.

3. Inverter:

The inverter is the heart of the VSD, converting the DC voltage back to AC voltage with variable frequency and amplitude. This conversion is achieved using power electronic devices like Insulated Gate Bipolar Transistors (IGBTs).

4. Control Unit:

The control unit, typically a microcontroller or DSP (Digital Signal Processor), manages the overall operation of the VSD. It controls the switching of the IGBTs in the inverter to produce the desired output frequency and voltage.

How VSDs Control Motor Speed

speed of a AC motor is determined by a frequency of the AC power supply. By adjusting the frequency of the output voltage, the VSD can control the motor speed. This is done through Pulse Width Modulation (PWM), a technique where the inverter generates a series of voltage pulses at varying widths to simulate a sinusoidal AC waveform. By varying the frequency of these pulses, the VSD adjusts the motor speed accordingly.

ATV (Altivar) Drives

Altivar drives, manufactured by Schneider Electric, are a popular series of VSDs known for their robust performance, energy efficiency, and advanced control features. These drives are designed to meet the demands of various industrial applications, from simple motor control to complex automation systems.

Key Features of ATV Drives

1.Energy Efficiency:

ATV drives are designed to optimize energy consumption by adjusting motor speed to match the required load. This results in significant energy savings, especially in applications like pumps and fans where the load varies over time.

2. Advanced Control:

Altivar drives offer sophisticated control algorithms, including sensorless vector control and flux vector control, providing precise motor speed and torque control. This is particularly beneficial in applications requiring high dynamic performance and accuracy.

3.User-Friendly Interface:

ATV drives come with intuitive user interfaces and configuration tools, making them easy to set up and operate. They also feature communication capabilities with various industrial networks, facilitating integration into complex automation systems.

4.Reliability and Durability:

Built to withstand harsh industrial environments, Altivar drives offer high reliability and long service life, reducing downtime and maintenance costs.

Applications of ATV Drives

Altivar drives are versatile and used in a wide range of applications, including:

HVAC Systems:

For controlling fans and pumps to optimize energy use.

Material Handling:

In conveyors, cranes, and hoists, providing precise speed and position control.

Industrial Processes:

In mixers, compressors, and extruders, ensuring optimal performance and energy efficiency.

Conclusion

Variable Speed Drives, particularly the Altivar series, play a vital role in modern industrial automation, offering significant benefits in terms of energy efficiency, process control, and equipment longevity. Understanding their working principle helps in appreciating how these devices contribute to the advancements in industrial technology and operational efficiency.

.webp)

No comments:

Post a Comment